Our Products

Car Series

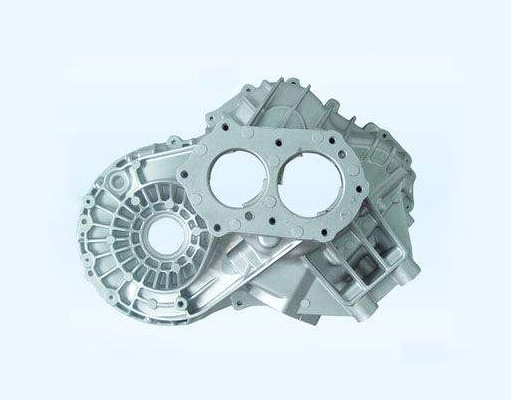

Precision die-casting molds have a wide range of applications in automobile manufacturing. By injecting molten metal into the mold under high pressure, complex structural parts such as engine housings and transmission housings can be quickly formed. These parts require high precision, high wear resistance, and high reliability. The application of precision molds ensures the accuracy and consistency of parts and improves the performance and efficiency of automobiles. In addition, the optimization and innovation of mold design help to achieve vehicle lightweighting, reduce energy consumption, and improve fuel economy. In short, precision die-casting molds play a key role in automobile manufacturing and promote the continuous development of the automobile industry.

Mold Display

Precision die-casting molds have a wide range of applications in the field of mold manufacturing. They employ high-precision machining technology to ensure the ultimate precision and durability of the molds. Die-casting molds play a significant role in the automotive industry, electronic products, aerospace, and medical devices. They can not only manufacture complex metal parts but also ensure high precision and quality stability of products. In addition, their efficient production capacity and low manufacturing costs bring significant economic benefits to enterprises. In summary, precision die-casting molds have become an indispensable part of modern manufacturing, driving the advancement of mold manufacturing technology.

Communication Series

Precision die-casting molds have a wide range of applications in the field of communication equipment. The precise manufacturing of molds provides a high-quality foundation for the parts of communication equipment. For example, in mobile phone manufacturing, die-casting molds are used to manufacture key components such as casings and internal structural parts, ensuring the structural stability and beautiful appearance of the equipment. In the manufacturing of network equipment such as routers and base stations, die-casting molds also play a key role in ensuring the precision of the internal structure and the stability of the performance of the equipment. The manufacturing technology of molds continues to advance, meeting the needs of communication equipment for high precision and high quality, and promoting the continuous development of the industry. Therefore, precision die-casting molds play an indispensable role in the field of communication equipment.

Electric Tools Series

Die-casting precision molds have a wide range of applications in the field of power tools. The precise manufacturing of molds enables high-precision and high-efficiency production of power tool parts, such as motor housings, gearboxes, and handles. The material and process of the mold ensure the high durability of the power tools, allowing the tools to maintain stable performance during long-term use. In addition, the application of precision molds makes the appearance of power tools more refined and improves the market competitiveness of the products. Therefore, die-casting precision molds play a vital role in the application of the power tool industry, promoting the continuous development of the power tool industry.

Car Series

Precision die-casting molds have a wide range of applications in automobile manufacturing. By injecting molten metal into the mold under high pressure, complex structural parts such as engine housings and transmission housings can be quickly formed. These parts require high precision, high wear resistance, and high reliability. The application of precision molds ensures the accuracy and consistency of parts and improves the performance and efficiency of automobiles. In addition, the optimization and innovation of mold design help to achieve vehicle lightweighting, reduce energy consumption, and improve fuel economy. In short, precision die-casting molds play a key role in automobile manufacturing and promote the continuous development of the automobile industry.

Mold Display

Precision die-casting molds have a wide range of applications in the field of mold manufacturing. They employ high-precision machining technology to ensure the ultimate precision and durability of the molds. Die-casting molds play a significant role in the automotive industry, electronic products, aerospace, and medical devices. They can not only manufacture complex metal parts but also ensure high precision and quality stability of products. In addition, their efficient production capacity and low manufacturing costs bring significant economic benefits to enterprises. In summary, precision die-casting molds have become an indispensable part of modern manufacturing, driving the advancement of mold manufacturing technology.

Communication Series

Precision die-casting molds have a wide range of applications in the field of communication equipment. The precise manufacturing of molds provides a high-quality foundation for the parts of communication equipment. For example, in mobile phone manufacturing, die-casting molds are used to manufacture key components such as casings and internal structural parts, ensuring the structural stability and beautiful appearance of the equipment. In the manufacturing of network equipment such as routers and base stations, die-casting molds also play a key role in ensuring the precision of the internal structure and the stability of the performance of the equipment. The manufacturing technology of molds continues to advance, meeting the needs of communication equipment for high precision and high quality, and promoting the continuous development of the industry. Therefore, precision die-casting molds play an indispensable role in the field of communication equipment.

Electric Tools Series

Die-casting precision molds have a wide range of applications in the field of power tools. The precise manufacturing of molds enables high-precision and high-efficiency production of power tool parts, such as motor housings, gearboxes, and handles. The material and process of the mold ensure the high durability of the power tools, allowing the tools to maintain stable performance during long-term use. In addition, the application of precision molds makes the appearance of power tools more refined and improves the market competitiveness of the products. Therefore, die-casting precision molds play a vital role in the application of the power tool industry, promoting the continuous development of the power tool industry.

Integrated Solutions for Efficient Transportation and Mould Manufacturing

Suzhou Yongjia Precision Mould Factory

Founded in 2003

Suzhou Yongjia Precision Mold Factory was founded in 2003 and is located in Weitang Town, Suzhou City, which is known as the "Town of Pearls", only three kilometers away from the Ring Expressway. Yongjia factory covers a total area of approximately 15,000 square meters and is a factory specializing in the design and manufacture of die-casting precision molds and the production and processing of die-casting parts.

Yongjia has import and export rights, and its die-casting parts and plastic parts are exported to Sweden, Germany, South Korea, Japan and other places. In 2015, a new company, Suzhou Kangsuo Electromechanical Co., Ltd., was successfully invested and established in Suzhou Auto Parts Base, with a total plant area of approximately 20,000 square meters, specializing in the production of large auto parts castings, precision mold design and production, and finished product assembly. At present, our company has advanced CNC machining centers, spark machines, wire cutting, milling machines, and other large and small mold equipment more than 20 sets, fully automatic molding die-casting machines 125T-1650T more than 20 sets, CNC precision drilling and milling center 100 sets, and various other mechanical processing equipment, equipped with advanced three-dimensional, X-ray flaw detector, projector, optical spectrum analyzer, height gauge and other quality assurance testing equipment. Main products include: auto parts, communication parts, power tools, household appliances, textile machinery.

Latest News

Join Us

Sustainable development, good business expansion

Establish diversified talent introduction channels to attract outstanding talents from all over the world.